Offering you all types of hot forging, we work with carbon steel, stainless steel, copper and alloy to create bolts, blanks, tools, pegs & much more...

Range of forging products

Hot Forged in the UK

Other Products

Rapid EPS Rapid Post

The perfect example of Multi-Stroke's bespoke metal manufacturing services, the Rapid EPS system offers a revolutionary assembled edge protection for construction workers, with only minimal training.

WoodBlocX Modular

Garden Features

WoodBlocX’s innovative and modular garden features made a successful pitch on BBC’s Dragons’ Den and each kit includes ground spikes forged by Multi-Stroke.

Holland & Holland

Rifle Barrels

The tubes that become the barrels for Holland & Holland’s world-class sports guns and rifles are forged by Multi-Stroke, in the heart of the West Midlands.

<

>

Case Studies

One of the UK’s unique forging companies, Multi-Stroke offers a range of forging activities, including Conventional Horizontal Upset Forging, Electrical Upset Forging and Vertical Press Forging.

Hot Forging – Horizontal

Conventional Horizontal Upset Forging methods are used to gather and displace metal to the desired form or profile. Normally products and components are forged from round stock materials and are heated using Induction Heating.

Upset Forging, or “heading”, is the process of increasing the parent material diameter by controlling the volume of gather using dies (tools), ensuring sufficient material is headed to produce a given profile or shape.

Typically components manufactured by forging have significant strength and a uniform material structure.

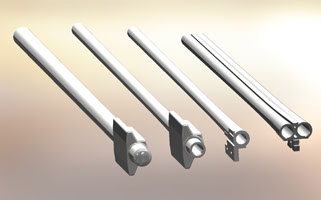

Conventional Horizontal Upset Forging Products

Conventional Horizontal Upset Forging Products

• Headed bolt blanks: hexagon, round head, flat profile

• Anchor pins

• Ground spikes, tent pegs & marquee stakes

• Anvil bolts

• Bespoke items

Hot Forging – Electrical Upset Forging

This unique forging process allows the gather of material to be far greater than conventional methods. The material is heated and formed using resistance heating and hydraulic pressure. The combined effect can create a large gathered ball or cone shape which can be further formed in dies on Vertical Presses to produce a component with a large head profile or shape, with a relatively small parent bar. Strength and structure characteristics are superior.

Electrical Upset Forging Products

Electrical Upset Forging Products

• Headed bolt blanks: hexagon, round head, flat profile,

tee & offset profiles

• Eyebolts: cylindrical and flattened

• Flattened head tee bolts

• Gear lever

• Hand tools

• Bespoke items

Hot Forging – Vertical Press Forging

Preforms from Horizontal or Electrical Upset Forging can be finished forged using Vertical Forging presses. Also, direct forging from common stock materials (which do not need to be preformed or gathered) can be forged. Products to be forged can be heated and forged in dies (tooling) into a variety of shapes and profiles. The ability to combine the activities and processes enables Multi-Stroke to offer custom and specialised products, with the potential of reducing the material required to manufacture when compared with other forging processes and machining from solid bar stock.

Muilti-Stroke Hot Forging – Special Applications

We have an Electrical Upset Forging cell which has the facility to handle forging preforms on long bars up to 10.5m, maximum diameter 20.0mm.

Types of metal forged by Multi-Stroke

We are able to forge in a range of materials including: Carbon Steels, Stainless steels, Alloys and Copper.

Markets Served by our Hot Forging

Multi-Stroke offer hot forging services to the following industries: Automotive, Agricultural, Heritage, Lifting, Nuclear, Construction, Petrochemical, Leisure, Mining, Ornamental, Power Generation, Transportation, Aerospace, Hand tools and Marine.

Hot Forging Equipment – Capacities

• Conventional Upset Forging: Bar diameters up to 25.0mm.

• Electrical Upset Forging: Bar diameters up to 35.0mm.

• Vertical Press Forging, Direct Heating: Bar diameters up to 60.0mm

Multi-Stroke Limited, Locarno Works, Locarno Road, Tipton, West Midlands DY4 9AF United Kingdom

© Copyright 2019 Multi-Stroke Limited