Multi-Stroke Case Study: Holland & Holland

Case Studies

“These forgings, as supplied from Multi-Stroke, have proved consistently to give us an excellent start to this very exacting process.”

Holland & Holland’s shotguns and rifles have been made in London since 1835 and are widely regarded as the finest bespoke sporting guns and rifles in the world.

Hand carved and shaped by highly skilled craftsmen to fit the customer to within a thousandth of an inch, these guns are the benchmark for excellence in the guntrade.

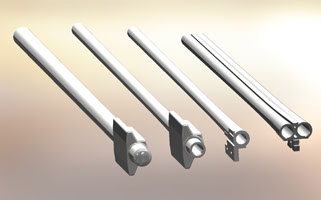

Based in the heart of England, and experts in forging, Multi-Stroke are involved at the start of this highly precise manufacturing process, forging the tubes for double barrel shotguns and riffles. These are then are turned, drilled, bored, honed, milled then brazed together to exacting concentricity and finish requirements.

Based in the heart of England, and experts in forging, Multi-Stroke are involved at the start of this highly precise manufacturing process, forging the tubes for double barrel shotguns and riffles. These are then are turned, drilled, bored, honed, milled then brazed together to exacting concentricity and finish requirements.

“These forgings, as supplied from Multi-Stroke, have proved consistently to give us an excellent start to this very exacting process,” explains Holland & Holland’s Technical Design Manager John Sperinck. “We have found Multi-Stroke to be competent and professional together with friendly and helpful staff. We would recommend them to anyone with a need for regular consistent forging supplies.”

Today Holland & Holland use the most modern CNC equipment and CAD design features, combined with all the traditional gun making methods. These techniques include actions filed to great precision using the "oil smoke black" method, hand struck barrels, hand shaped stocks and checkering. Depending on the model of gun, from 650 man hours to well over 1250 man hours will be involved making it. No part of a Holland & Holland gun is interchangeable, it is always made specially for the gun down to the smallest pin!

Today Holland & Holland use the most modern CNC equipment and CAD design features, combined with all the traditional gun making methods. These techniques include actions filed to great precision using the "oil smoke black" method, hand struck barrels, hand shaped stocks and checkering. Depending on the model of gun, from 650 man hours to well over 1250 man hours will be involved making it. No part of a Holland & Holland gun is interchangeable, it is always made specially for the gun down to the smallest pin!

Multi-Stroke Director Ian Wright added: “We’re honoured to be trusted by this world class British manufacture, with its long history of excellence, to provide these hot forged components for their guns and rifles.”

Find out more at the Holland & Holland website

Twistlocks

Full range of Twistlocks (trailer to container locks) for road and rail applications. Can be used on trailers including chassis, platform, rigid or skeletal. We offer retractable or non retractable Twistlocks (standard or screw down)…

Handbrakes

Trailer handbrakes (manual park brake) for use with any size of trailer or ancillary equipment trailer. Agricultural (tipping, dumper, flat, low loader, livestock floats), industrial, skeletal, platform or chassis. MS45 and MS55 types…

Complete Products

Our engineering and design staff can work with detailed drawings or just an idea of what needs to be achieved, creating that unique component or complete product for you. Using any combination of fabrication / welding, press work and machining, manual and semi automatic MIG, CNC, bench production and assembly…

Forgings

All hot forging work including horizontal upset forging, vertical press forging and electrical upset forging. We work with carbon steel, alloys, stainless steel and copper. Products include eye bolts, anvil bolts, expanding bolts, forge blanks, hand tools, tent pegs…

Pressings

Bespoke metal pressing, metal stamping, metal forming, crop & blank. Secondary & Progression. Strip or Coil Fed. Aluminium, brass, carbon steel, copper and stainless steel. All custom metal manufacturing. With mechanical presses from 10 to 160 ton…

<

>

Other Products

Multi-Stroke Limited, Locarno Works, Locarno Road, Tipton, West Midlands DY4 9AF United Kingdom

© Copyright 2019 Multi-Stroke Limited